DeCarice has developed an innovative Hydrogen dual-fuel direct-injection retrofit technology.

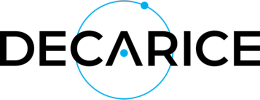

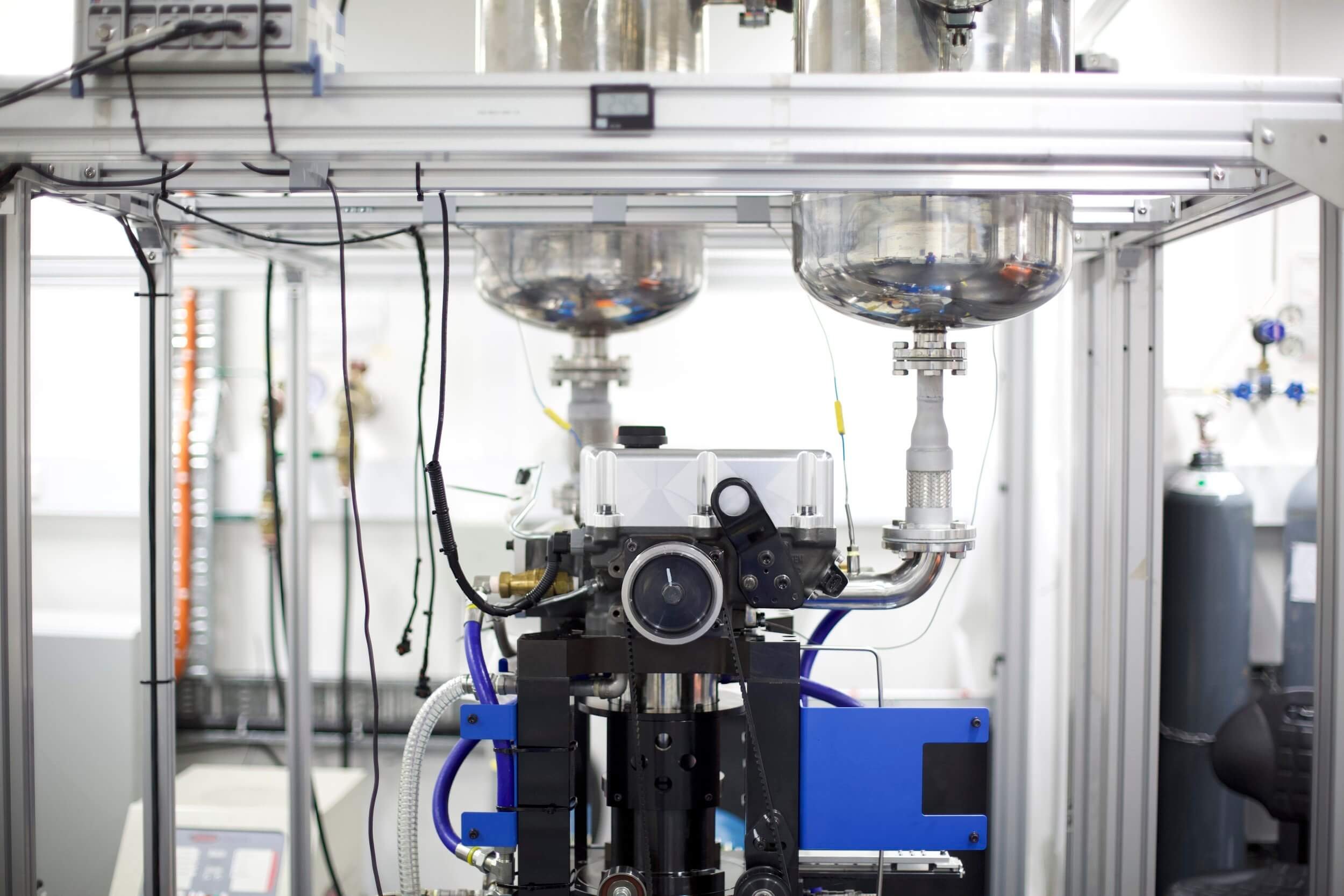

The dual-fuel direct injection system is a set of hydrogen gas injectors and supporting systems which operate alongside the existing diesel injection system.

The existing engine structure and ancillary parts are retained, minimising disruption to operational and maintenance procedures.

Technology Overview

Hydrogen direct injection for superior hybrid mixture control

Live hydrogen-diesel mode switching without the need for shutdown

Substitution of 90%+ hydrogen gas for 70%+ carbon output reduction

Insensitive to hydrogen purity relative to fuel cell systems

CO2 impact

Engine-out carbon dioxide levels are reduced by 70+% when substituting 90% hydrogen for diesel. Substitution directly removes the carbon-containing portion of the engine’s fuel.

CO and other C compounds

Engine-out carbon monoxide and uHC/particulate levels are reduced under typical lab equipment detection limits when operating at 90% substitution.

NOx impact

Dual-fuel direct injection uniquely enables engine-out NOx levels to be maintained at the diesel baseline. This is superior to other hydrogen ICE retrofits and results from the combustion expertise applied to this problem.

Industrial Applications

DeCarice’s dual-fuel direct injection technology is ideally suited for high-uptime heavy industrial diesel fleets. We work with companies operating engines across industry sectors.

Heavy Transport

Stationary Power

Logistics & Ports

Mining

Hydrogen Economics

Dual-fuel direct injection brings diesel fleet and business operations into the hydrogen ecosystem.

We will support you in understanding how to integrate industrial quantities of hydrogen gas into your day-to-day operations.

Analysis of existing diesel fleet usage

Projection of dual-fuel impact

Hydrogen supply into operations